704-602-4106 | Charlotte, NC | Mon-Fri: 8:00AM-4:30PM

Contact Form HP

We will get back to you as soon as possible.

Please try again later.

APPLICATIONS

End Use Applications For Compounds & Master Batches

Our customers’ compounds and master batches serve a wide range of industries, including automotive, textiles, home goods, recreation and practically anywhere there is plastic.

The Polymers Technology Center provides custom engineered compounds for the most challenging applications. These technologies are appropriate for processing methods such as injection molding and extrusion.

The experts at the Technology Center have the expertise to configure our equipment to produce the best compound for your application.

Industries And Applications

Plastic products in almost every industry are used every day. High-performance polymer compounds are needed that meet the rigorous performance requirements of individual industries. Learn how the Polymers Technology Center is helping companies with the manufacture of engineered polymers, engineered composites, masterbatch and more.

Automotive

Polymers are used by automotive manufacturers when creating parts for cars and other vehicles. And they are many. Overall, auto manufacturers need plastics that are strong, lightweight, comfortable, and impact-resistant.

When it comes to a vehicle’s exteriors, polymers are used in bumpers, panels, moldings and more; these applications require material characteristics that include strength, stiffness, impact-resistance, and paintability. What’s needed for a car’s interior includes polymers for injection molding that become foams for seating that are safe and comfortable; elastomers and resins that last a long time and perform well, and much more. Under the hood parts, such as tubing, belts, adhesives, and coatings require compounds that provide excellent heat and chemical resistance, low friction and high durability and reliability.

Consumer Goods

Consumers around the world have exceptionally high expectations of the items they spend their money on; items such as apparel, bedding, flooring, seating, furniture, kitchen and electronic appliances, and power tools. They want a high level of comfort, style, durability, and performance. They also want materials that are environmentally-friendly and cost-effective. A wide range of compounds are needed for manufacturers to meet these expectations.

Packaging

There are as many different kinds of packaging as there are products – from coffee cups, water bottles, and containers for household cleaners to medical packaging and protective films. A wide range of polymers are developed every day to meet the various needs of packaging companies who are creating the containers we use.

The right polymer materials make it possible to develop exciting new packages that deliver strong, safe, cost-effective, recyclable options. Packages ranging from flexible or rigid to molded or extruded.

Medical Equipment

Thermoplastics compounds are ideal for medical-grade plastics used in medical devices and components. Some thermoplastics, such as Polyethylene, Polypropylene and Polymethyl methacrylate are ideal for use with medical devices since they provide temperature resistance and corrosion resistance properties. Common medical products made with thermoplastics include plastic medical tubing, surgical instruments, dental instruments, sterilization trays and diagnostic equipment.

Sporting Goods

In the last decade, there has been an increased demand for the utilization of thermoset polymers and other specialty plastics in the creation of sporting products, equipment and activewear. Surfboards, tennis rackets, playground equipment, sneakers, golf clubs, and many other types of activewear are currently made using the latest innovations in specialty plastics.

Some of the specialty plastics used in athletic wear and gear include polyurethane, polycarbonate, nanotechnology and fluoro technology.

Construction

Polymer producers manufacture the building materials the construction industry needs, from insulation and waterproofing to household goods such as window shutters and architectural profiles. A wide range of compounds are produced worldwide to meet the stringent regulations required, as well as the design needs of the building contractors.

Plastic Recycling

The Polymers Technology Center can assist companies that recycle plastics by analyzing the recycled flake to determine whether it is a viable material for its intended application.

Our partnership with the Polymers Center allows us access to a Sesotec Flake Scan System. With this equipment, we can analyze samples by polymer types, colors, and metal particles within minutes and determine the quality of plastic flakes. One of the challenges to processing recycled plastics is to know if you have a consistent source of material. The Sesotec analyzer can help with the quality control of your incoming material. The Polymers Technology Center can further address the needs of the Plastic Recycling Industry by plastic processing.

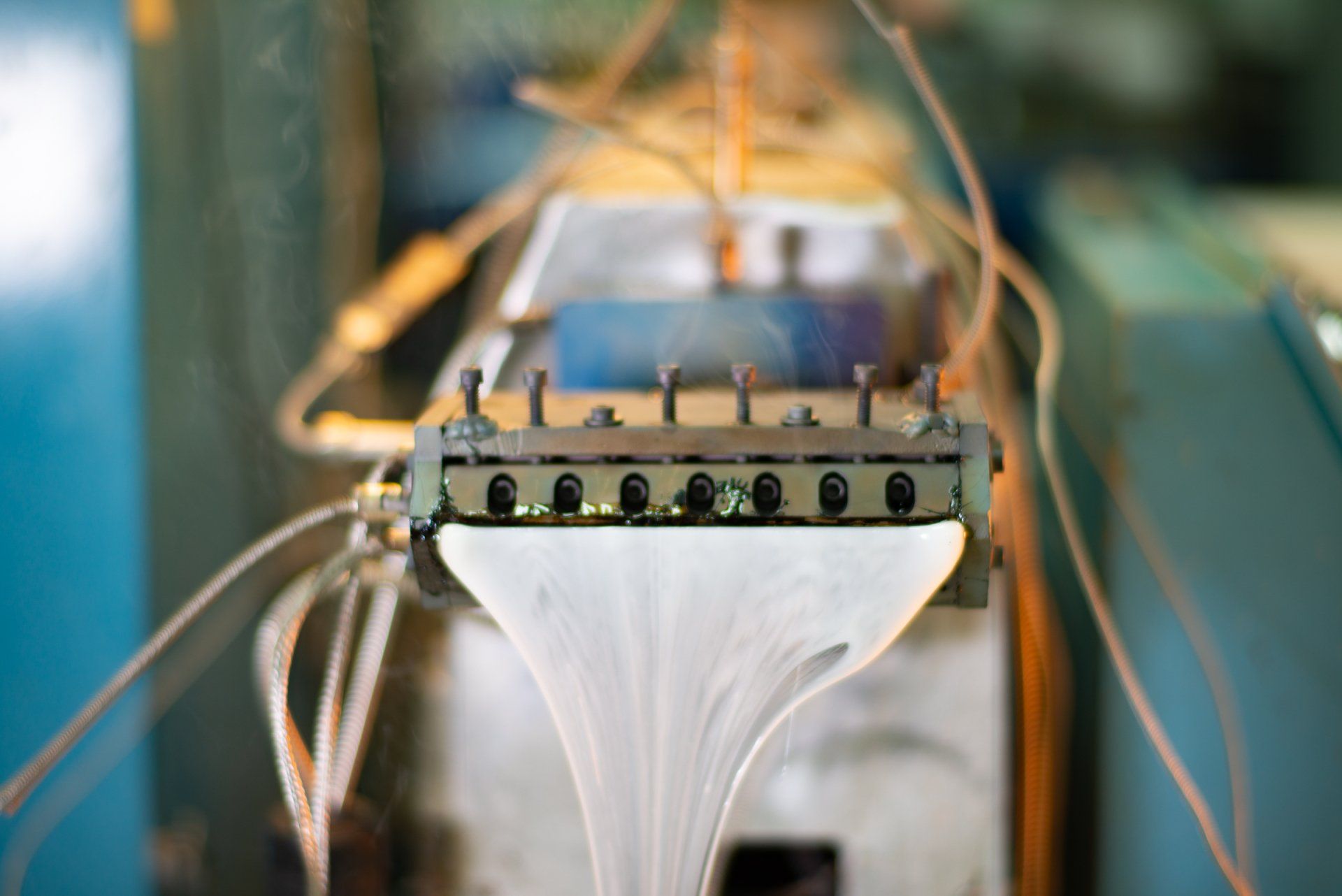

Producing A Custom Compound

The compound development process begins with a recipe for your unique application. Whether you are incorporating additives, fillers, modifiers, and reinforcing agents, The Polymers Technology Center starts by producing samples for pre-production trials. Once the material is acceptable, our team of engineers and technicians are with you every step of the way to ensure a consistent, quality product.

Contact Us

Have a question? Call Today!

University Research Park

8900 Research Drive

Charlotte, NC 28262

Let Us Know

Copyright 2012 - 2022 | Polymer Technology Center | All Rights Reserved