Contact Form HP

We will get back to you as soon as possible.

Please try again later.

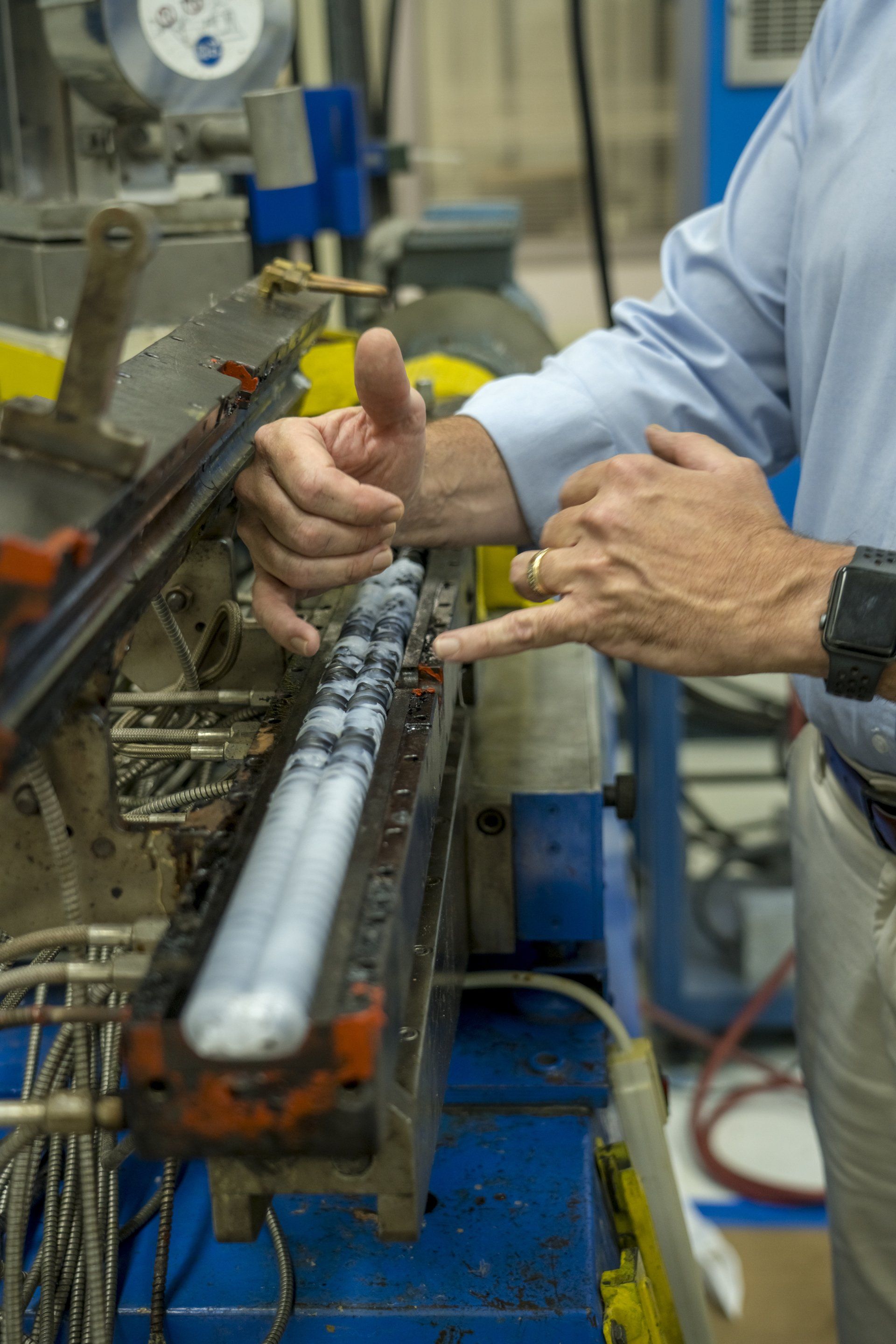

Extrusion

Polymer Extrusion Equipment and Machinery

Polymers Technology Center in Charlotte, NC

Extrusion is the process of shaping plastic material into a fixed cross-sectional profile. The polymer is pushed through a die of the desired cross-sectional profile and molded into an array of simple or complex shapes.

To ensure you get the shape you need, The Polymers Technology Center in Charlotte, NC, houses three extruders ready for use. Dies are mounted on the extruder, and once the polymer material is heated and melted, it is forced through the die to create the desired shape. It is then cooled, solidifying it into the shape you need.

Combining our staff's expertise and advanced equipment, we can efficiently extrude polymer materials to create a wide variety of high-quality products. To learn more about the process and how custom plastic extrusion works, contact a Polymers technician today.

The Polymer Extrusion Process

Polymer Material Introduced

Blended plastic material is introduced into the polymer extrusion machine, where it slowly funnels into the screw extruder.

Heated and Melted

The material is exposed to intense heat so it can be melted. It's important to make sure it is melted down so it can go through the cross-sectional die and be formed into the desired shape.

The Extruder and Die

The molten plastic is then forced through the appropriately-shaped die. It is viscous enough to form into the shape you need but thick enough to retain that shape once it leaves the die.

Cooling Bath

The still-heated plastic is run through a uniformly-cooled bath, designed to solidify the plastic into the desired shape.

Pull Roller

Pull rollers are designed to provide pulling pressure (to help plastic through the extruder and the cooling bath) while also smoothing it out.

Plastic is Cut

The final step involves cutting the material into the dimensions you need. From there, your product is ready to be tested and whatever else you have planned.

Types of Extrusion

- Sheet film

- Blown film

- Overjacketing

- Profile

- Coextrusion

- Extrusion coating

Product Development Trials

The plastics industry is built on rigorous trials and constant innovation. The Polymers Technology Center helps industry-leading manufacturers test new products and specialty compounds, research new resin and additive combinations, and optimize production processes.

For trials, we use laboratory-scale equipment. This provides the user the flexibility to work with small amounts of material. The process can be scaled up to larger production as the material becomes more refined.

Reactive Extrusion

Polymers Tech uses innovative equipment capable of combining chemical reactions that are normally handled separately in the process. With the use of twin-screw extruders, you can seamlessly combine monomers into one polymer, or directly modify the material itself, all within a singular extrusion process.

Our plastic extrusion machines provide excellent mixing capabilities and product handling, allowing you to seamlessly incorporate more complex processes into a single step. The result is a streamlined and efficient production process.

Contact Our Plastic Extruder Technicians in Charlotte, NC

Polymers Technology's extruder facility in Charlotte, NC is equipped with the latest technology and equipment. With our hardware, you will be able to manufacture plastic materials quickly and efficiently, allowing you to test and inspect products regularly. With our high-quality equipment and efficient process, testing and trials can go much faster, allowing you to perfect your final product and put it to use faster.

For more information about our extrusion machinery, contact a Polymers technician today.